Case Studies

Fulton Hogan

The Challenge

Fulton Hogan, a major contractor with a strong presence across the South Pacific and Australia, is known for delivering on promises and maintaining high standards. In 2012, during the redevelopment of their regional headquarters, they aimed to enhance water management to prevent the use of wet aggregate in bitumen production. The Project Manager also saw an opportunity to improve yard efficiency by upgrading the outdated, unsafe aggregate storage system.

The Solution

Fulton Hogan invited Interbloc to propose a storage solution for their yard, outlining six key criteria:

- Minimize water contamination in aggregate bunkers.

- Ensure easier access for truck drivers to facilitate quick delivery of aggregate.

- Prioritize Health & Safety by providing a highly stable containment solution.

- Offer a cost-effective design engineered to high standards.

- Provide flexibility to accommodate varying aggregate volumes throughout the year.

- Align with the company’s corporate sustainability mission.

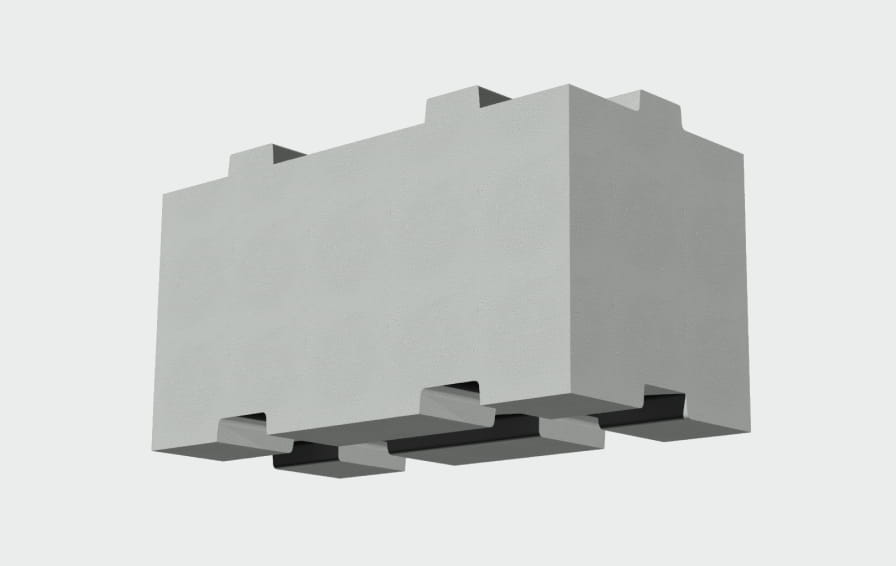

Interbloc designed two 6-bay bunkers, each measuring 40 meters in length and 20 meters in depth, with a total capacity of 2,500 cubic meters. The design ensured efficient water drainage from the site and was fully engineered to meet Fulton Hogan’s stringent health and safety standards.

The feedback since the site's redevelopment has been overwhelmingly positive.

The Benefits

Alwyn van der Linde, Regional Manufacturing Manager, notes that Interbloc secured the project due to its fully engineered solution aimed at improving truck flow efficiency and enhancing health and safety. "The bunkers were custom designed and engineered to meet our strict standards," Alwyn explains. "We also appreciate that the solution is reusable if our needs change in the future. Interbloc's proven track record and strong partnerships in the construction industry made them an ideal choice."

Truck drivers now find deliveries faster and easier, thanks to the yard's cleaner, more organized layout. Fulton Hogan successfully improved the site's water management while reinforcing their commitment to a safe and healthy work environment.