Case Studies

Fulton Hogan: Quarry Hopper

The Challenge

Fulton Hogan is a leading organisation within the construction industry, boasting over 80 years of experience in transport, water, energy, mining, civil construction, and land development infrastructure across New Zealand, Australia, and the South Pacific.

One of Fulton Hogan's clients required a 6-metre-high hopper pit for a quarry, where aggregates would be dumped and processed. The hopper is loaded from the top by a lorry and trailer, which then feeds into a conveyor system that passes through a screening plant. The project also required a ramp for lorries and trailers to ascend to and descend from the hopper, with the additional capability of being manually loaded from one side.

The Solution

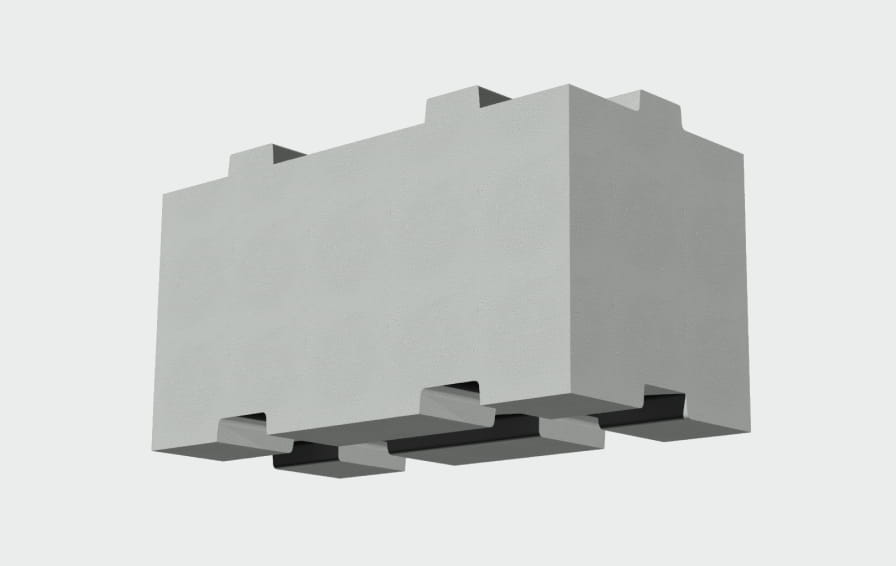

Fulton Hogan found the solution with Interbloc's modular wall system for the construction of the quarry hopper. Interbloc provided a 6.6-metre-high design, which was then engineered and evaluated by Tiaki Engineering Consultants.

The engineering included ground specifications, concrete foundations, vertical tie-down rods, and horizontal steel strapping. Construction began with the foundation work, preparing the structure for the wall construction. The entire structure was completed within five weeks from the completion of the foundation work, with minimal issues.

The Benefits

Fulton Hogan's customer and the construction team were pleased with the end result of the quarry hopper and the time frame in which it was completed. Interbloc's heavy-duty blocks created strong walls that outlined the lorry ramp and sides of the pit, while their modular quality made the structure quick and easy to build.