Case Studies

Well Connected Alliance

The Challenge

Well Connected Alliance has been entrusted with the construction of the country's largest roading project to date. This monumental development, known as the Waterview Connection, is a $1.4 billion initiative that involves building 4.8 km of six-lane motorway.

Even more ambitious is the fact that half of this motorway will be underground, making it the largest road tunnel in Australasia. The extensive tunnelling process generates a significant amount of excess water, which must be stored and treated. This is where Interbloc plays a crucial role.

The Solution

Interbloc was contracted to supply blocks for the project and construct a two-bay settling pond due to several key factors. McConnell Dowell, a partner of Well Connected Alliance, selected Interbloc for the settling ponds because the blocks were engineered for ease of removal at the end of the project.

As Interbloc Account Manager Dion Rout explains, Interbloc offers solutions that save customers time, money, and hassle. "Since the project was only scheduled for two years, Well Connected Alliance needed a system that could be dismantled once it was completed," he says. "The flexibility of Interbloc made this an ideal choice. With such short time frames, Interbloc was the quickest and most cost-effective option. Installing an alternative system—such as solid concrete—would have taken much longer."

Interbloc's unique Buyback Guarantee also played a crucial role in securing the contract. The scheme provided the customer with a level of security and assurance that only Interbloc could offer. "The added benefit of the Interbloc Buyback Scheme is that at the end of the project, we take care of the blocks," Dion says. "This was a decisive factor because they only needed the blocks for a specific timeframe. We are confident in the quality of our blocks and are happy to take them back."

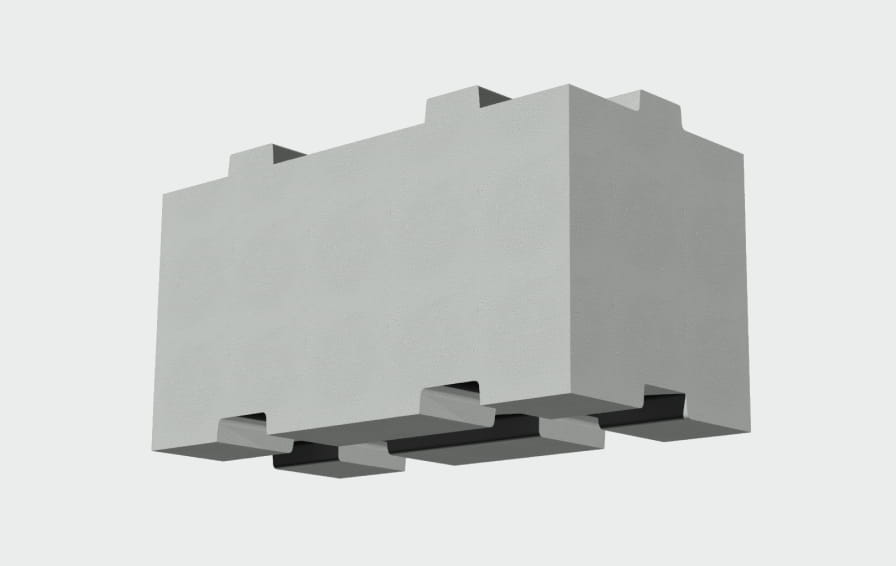

A total of 369 x 1200mm blocks and 9 x 1800mm blocks were used to create 130 linear metres of wall, reaching 1.8 metres in height. The wall was sealed using shotcrete, providing a watertight solution.

The Benefits

Within two weeks, the blocks were decommissioned from the Viterra site, transported, and reinstalled at the IPL site, where they are now used for storage. The modular design of the blocks allowed them to be arranged in a new layout tailored to IPL's requirements.

At Viterra's Geelong and Adelaide sites, the buildings were returned to their original condition without the need for demolition or time-consuming activities.